Extrusion

In this step, the WPC material is extruded through a machine to form the basic shape of the door panel. The material is heated and forced through a die to create the desired profile.

Gluing

After extrusion, if necessary, additional adhesive may be applied to certain parts of the door panel to enhance bonding or attach additional components.

Film Application

A protective film is applied to the surface of the door panel to protect it from scratches, damage, or environmental exposure during handling and transportation.

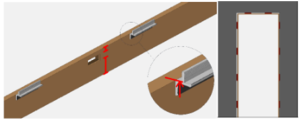

Film Cutting and Trimming

Once the film is applied, excess film is trimmed off and the edges are neatly cut to ensure a clean finish.

Vacuum Forming

In some cases, particularly for complex or decorative door designs, the door panels may undergo a vacuum forming process to achieve intricate shapes or textures.

Quality Inspection

Each finished door panel undergoes rigorous quality inspection to ensure it meets the specified standards and requirements. This may include checking for dimensional accuracy, surface finish, adhesion of film, and overall structural integrity.